Illinois is home to 14,660 manufacturing companies that employ 774,768 individuals.

Accordingly, it makes sense that the state does all it can to keep the industry thriving and encourage it to grow. U.S. manufacturing is currently facing three challenges:

- Finding skilled, qualified and dependable personnel

- Managing global supply chain inconsistencies

- Making financially wise decisions during a period of high inflation

Finding Skilled Team Members

Fact is, 22 percent of manufacturing workers will be retiring in the next ten years. Although expected to make a difference in retirement decisions, the U.S. Census Bureau reports that the 2020 COVID pandemic had little effect on retirement plans of 55- to 70-year-olds in the manufacturing industry. While 5.5 percent said they were retiring earlier than expected because of the pandemic, 5.1 percent of the same age group in the manufacturing industry reported they expect to work longer than they had originally planned.

But the issue of finding those highly skilled in crucial manufacturing fields remains a difficulty for small and midsized manufacturers. It is affecting how much work manufacturers searching for long term opportunities believe they can handle. If the work doesn’t come to Illinois manufacturers because it will take too long to deliver, that project is likely to go to another state or even another country.

Such a development would be costly to a state’s revenue flow. That’s when state lawmakers begin to pay attention to the workforce dilemma and propose solutions.

In the 102nd General Assembly, during 2021 and 2022, Illinois set into motion a few grant programs to encourage urgently-needed skill development, as well as interest in developing career pathways.

One program noted by TMA attempted to address the skills gap issue by urging ninth through twelfth graders to consider careers and the training and skills those careers would demand in planning their studies. The bipartisan measure passed unanimously in both chambers of the Illinois General Assembly and was signed into law in May 2022.

Still, manufacturing has struggled to attract the next generation’s attention. The challenge manufacturers face is to pull in young people interested in coding and programming computers to combine with creating the tangible products manufacturing provides and today’s society demands.

Those partial solutions towards providing a skilled workforce ready for manufacturing’s advancing requirements could be years, if not decades, away.

As a result, more and more TMA members say they are finding it necessary to turn to automation and robotics to fill the skilled personnel void, especially for assembly work and repetitive tasks. The investments into automation are overwhelming for some of the smaller shops to consider, but most are finding that not investing in automation could be detrimental to a small company’s future.

Others are asking how federal and state immigration policies can be changed to allow more non-citizens to be trained and fill the growing personnel void in the manufacturing industry. The solutions seem possible, but nearly unable to implement in the current, highly polarized political scenario at federal levels.

Personnel Shortage = Supply Chain Issues

Where are the parts we need to complete production? Why do they cost so much when they arrive? And how can we predict what the final cost will be? These are questions every TMA member deals with.

Following the 2020 government shutdown, demand was high and suppliers couldn’t keep up. In order to get the supply chain started once again, prices soared as suppliers worked to get their customers what they needed.

Those manufacturers that depended on overseas suppliers became unable to fulfill demand as billions of dollars in orders were stuck at seaports. The delay caused needed products to cost more and more as the demand increased.

A shortage of transportation operators severely aggravated the delay just as the cost of diesel fuel skyrocketed beyond any expectations. For months, the global supply chain was disabled and nearly broken. The result? Inflation.

The Feds were forced to step in to try and slow rising prices by increasing interest rates. Borrowing slowed and predictions of a serious recession became louder and clearer.

And with such a dire outlook, the industry looks to the government at both state and federal levels to help their businesses survive the tumult rather than become an additional obstacle to overcome.

TMA Launched New Advocacy Effort

Encouraging manufacturing in Illinois is a cause that will benefit municipalities, counties, and the whole state – and isn’t a strictly partisan effort.

After reviewing TMA’s Legislative Scorecard last year, it became evident to TMA that small and midsized manufacturers needed to have a stronger voice and presence at the State Capitol.

As a result, TMA launched the Small and Midsized Manufacturers’ Caucus – the SaMM Caucus.

While other manufacturing associations emphasize how state legislation may or may not affect corporations with thousands of employees, TMA is laser-focused on representing those manufacturers that employ 1-500 individuals.

One by one, state lawmakers from both political parties began agreeing to join the caucus with hopes of learning more about the industry, how their constituents’ businesses thrive and survive, and naturally, how the policies they represent in Springfield can and may affect their constituents’ businesses.

The visits were eye-opening for both lawmakers and TMA members. TMA members shared business concerns, how their businesses worked, how they contribute to the community and their hopes for the future.

Lawmakers listened, spoke with business owners and employees, absorbed the impact of the businesses in their districts, and came away with different perspectives.

In the meantime, TMA’s Advocacy Team began watching closely proposed legislation, and evaluating how those proposals may affect TMA members – and setting a plan into motion to inform TMA’s SaMM Caucus members of their responses.

As this report is written, the Illinois General Assembly is in one of the busiest times of the sessions, with lawmakers at the Capitol discussing exactly what they want to become public policy – that includes measures that will affect TMA members.

As the first year of this session draws to a close in May, there will be more to report on what to expect in the months and years ahead for Illinois businesses.

What TMA Members Can Do to Affect Public Policy

• Keep up to date with policy developments via TMA’s weekly E-News Bulletin.

• Respond to calls for action from the TMA Advocacy Team as needed.

• Invite a lawmaker to visit your company – TMA will help organize it for you.

• Vote for and support candidates that understand and will represent small and midsized manufacturers’

perspectives on key issues.

• Let TMA know of challenges you face because of state policy. TMA will work with you and your lawmakers to see how those changes can evolve to make the business climate better in Illinois for small and midsized manufacturers.

Illinois manufacturers account for nearly 13% of the state’s total output, employing almost 10% of the workforce. That equaled nearly $115 billion to Illinois’ economy in 2021 alone.

Small and midsized manufacturers are crucial to Illinois’ welfare – and TMA believes they should be at the political bargaining table to share their perspectives on major business policy issues.

The time has come. And TMA – with the help of our members – is ready to have a part in manufacturing Illinois’ public policy on manufacturing.

From TMA’s March/April 2023 News Bulletin. By TMA News editor, Fran Eaton.

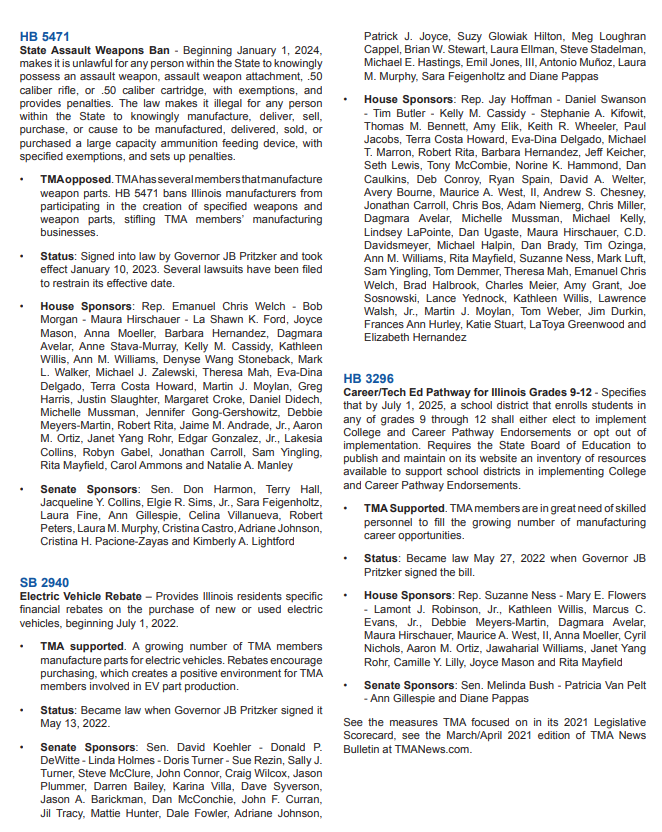

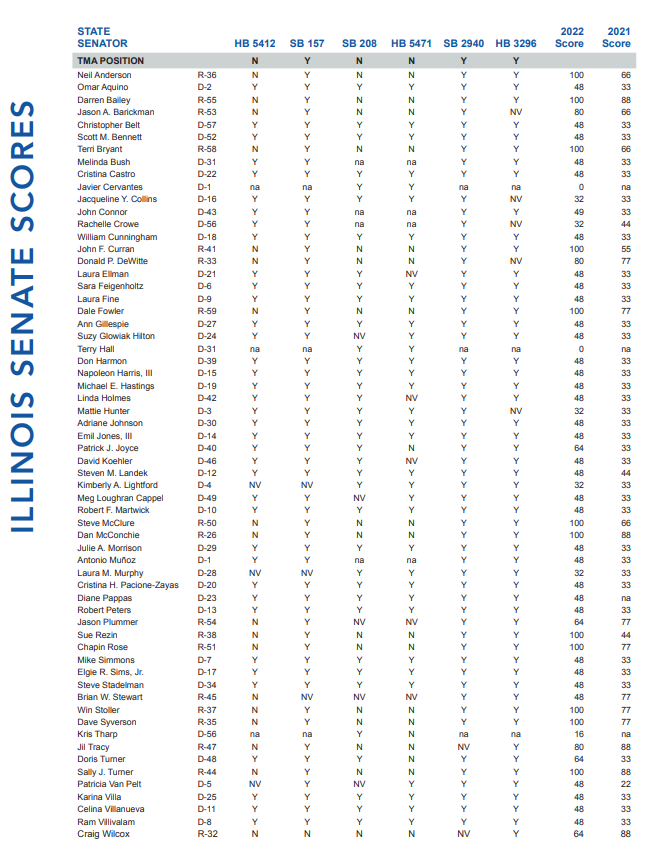

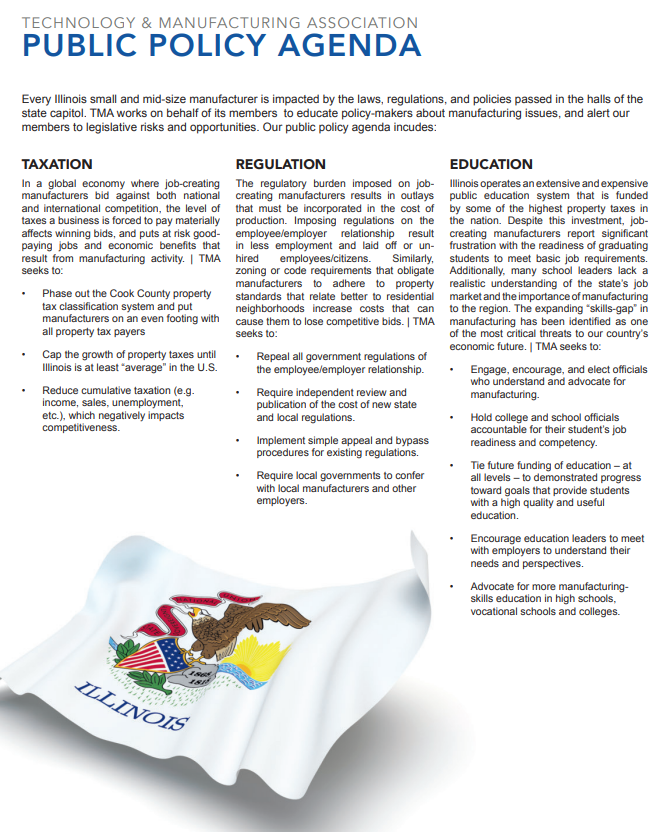

Find below TMA’s 2022 Legislative Scorecard, featuring how Illinois lawmakers voted in accordance with the Association’s Public Policy Agenda: